A New Way of Working

Jul 10, 2021

When people ask what anOrdain is all about, my first thought is ‘experimentation’. We’re a watch manufacturer, but we’re also a group of individuals from a myriad of design and engineering disciplines, fusing traditional craft with modern design. It’s that fusion and process of experimentation where progress is most often born.

Since selling our first watch in 2018, we’ve been busy. Enamelling is an inherently unpredictable practice - the risk of cracking and warpage is forever present. Starting out, we would produce three or four watches in a good week. Just as often, all the hard work would be scuppered and that number may be one or even none.

Thankfully, our production processes have been refined and our capacities improved since those early days, but genuine vitreous enamel will always take time.

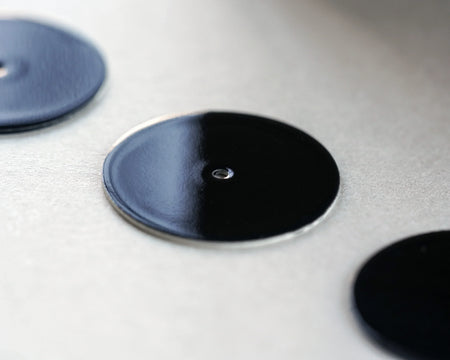

I know I speak for everyone here when I say there is a genuine appreciation at anOrdain for our customers. You're a patient and friendly bunch who allow us to do what we love, and there are many of you who get spoken about in the studio like old friends (as an aside, we were looking through a box of reject dials yesterday, and I was very taken by how the enamellers could reel off who each was for, what was wrong with them, why it happened etc., in what looked to me like a collection of perfectly good, mostly identical dials!).

So, letting anyone down with late deliveries is something we take to heart and, combined with the challenging nature of enamel and a constantly full order book, there is a perennial pressure on the team. The disruption caused by the events of the past year has only served to exacerbate this.

The biggest challenge faced at anOrdain is balancing production with developing new techniques and prototypes; we’re in the unusual situation whereby our production line is also our R&D department! Customer orders will always take priority, and rightly so. But this leaves us brimming with ideas and precious little time to spend exploring them.

With this in mind, we’ve decided to experiment with a system of batch production; we’ll alternate between periods spent on production and periods spent on development and place watches on the website when they are available, rather than making-to-order as we do now.

In all honesty, this is not an easy decision to make. We have a healthy and growing business with 16 mouths to feed every month, and the idea of turning off our income stream for several months is daunting. But, we have so much waiting to be explored and our current model of fitting development piecemeal around production is a poor use of time and potential.

It will do away with the lengthy build period on orders and I hope be a much more sustainable model - for you and us.

This new production method changes nothing when it comes to the care and time that goes into our watches. Our enamellers are still carefully hand-crafting every dial, our watchmakers still assembling and regulating each individual watch to match your requirements. We’ll just be able to dedicate uninterrupted time to this now, as we will R&D.

This new model will begin on Monday (12th of July), so if you are needing a watch in the next 2-3 months, there is still the opportunity to order before we switch over. We’ll keep you posted on batch release dates and look forward to sharing some exciting new watches. Please do get in touch with me if you’ve any questions.

Best wishes,

Lewis Heath

anOrdain Founder