Aluminium (at the lower end) or brass (at the mid-to-high end) is used for the base material before being coated in another substance such as nickel for a silver-look, or chemically treated to give a ‘blued’ look. Each hand is stamped out of a long thin sheet of brass or aluminium using a die (a cookie cutter!) and a hydraulic press. This process cuts the hand out, curves it if required, and creates a hole. Around this opening the material forms into a very shallow tube which attaches to the hands by friction to the respective hour/minute/second pipe from the movement.

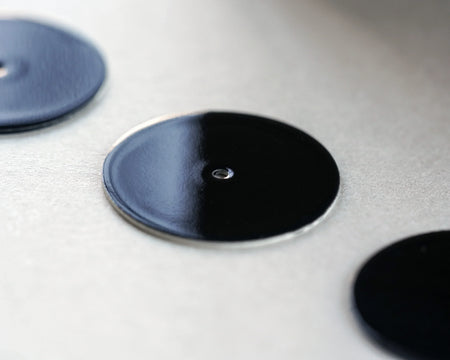

To create thermally blued hands, we need to use a particular type of high-carbon steel. Whilst brass is a relatively malleable metal, steel is not, and so it won’t press-fit onto the movement. To get around this we make the hands in steel and then create a ‘pipe’ for each one out of brass. These pipes are tiny, especially for the second hand, and each needs to be fixed to the steel hand before it’s affixed to the movement. To do this the pipe is made on a lathe with a miniscule chamfer in the top so that when it’s placed inside the steel hole in the hand it deforms evenly when struck with a hammer. Now that the pipe and hand are one, they can be attached to the watch.