Sunburst dial

May 10, 2023

Today we’re launching a new technique; new to us, and we think, new to watchmaking.

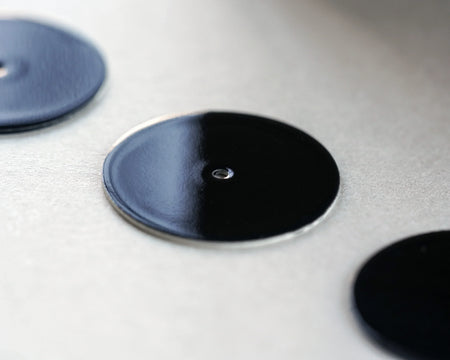

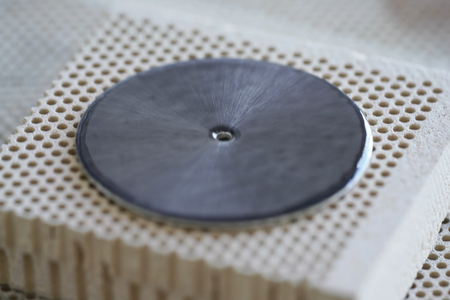

The watch in question combines three decorative styles in a single effect that is, we believe, a first. It features a sunburst pattern – common enough, but normally achieved in a machine process that involves spinning and brushing the dial. Our sunburst, however, has been hand-engraved: every minuscule score (around 1,120 of them) radiating from the centre is cut individually by hand. This is then layered up with coloured transparent enamel. It’s a simple idea: sunburst + hand-engraving + enamel. But the result is disarmingly beautiful, incredibly demanding to create, and unlike anything else we’ve seen.

Engraving the dial

Enamelling the dial

The finished dial

The finished dial

Case details

The Hodinkee Model 3